Airsoft Gases

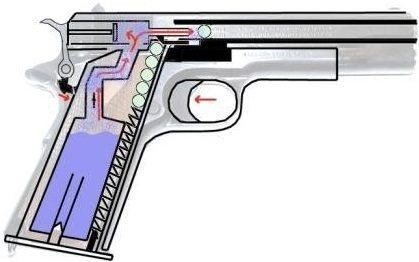

Gas propulsion in airsoft operates on the principle of releasing compressed gas from a magazine or cartridge. This gas then creates pressure that moves the piston, nozzle, or directly the BB through the barrel. In GBB guns, it also powers the slide for a realistic blowback effect. If you’re unsure which gas is best for your gun, check out our Guide to Choosing Airsoft Gas or reach out to us – we're here to help.

Types of gas propulsion by power (click on the heading to view available gas products on our e-shop)

- 1. Light Gas / HFC134a – a lower-power gas mainly for plastic guns such as Japanese Tokyo Marui. Lower pressure (~80 psi), gentle on internals.

- 2. Medium Gas - Green Gas – standard gas with a pressure of about 100–125 psi. Suitable for regular GBB guns, includes silicone for sealing lubrication.

- 3. Strong Gas - Red Gas and Black Gas / Propylene – higher-pressure gases (~130–180 psi), ideal for metal slides and sturdier gun constructions. Maintains performance in cold but increases wear on parts. Suitable for gas sniper rifles.

- 4. CO₂ – used in the form of 12g cartridges, high pressure (up to ~800 psi), extreme performance, and significantly stronger blowback. Not suitable for plastic slides or most pistols with basic alloy internals. CO2 requires investment into steel or aluminum trigger mechanisms and other durable gun parts.

- 5. HPA – external high-pressure air source (adjustable), extremely consistent performance, ideal for competitive play like SpeedSoft or precise DMR rifles and high-rate-of-fire SMGs.

Differences between gases

Propulsion | Pressure (approx.) | Advantages | Disadvantages |

|---|---|---|---|

HFC134a | ~80 psi | Gentle on internals, suitable for plastic guns | Low performance, unsuitable for cold weather |

Green Gas | ~100–125 psi | Standard performance, easy to use | Temperature sensitive |

Red/Black Gas | ~130–180 psi | High performance, works well in cold | Increased wear on seals and internals |

CO₂ | ~800 psi | Extreme power, strong blowback | Requires sturdy construction, internal wear |

HPA | Regulated (typically 80–160 psi) | Top performance consistency, quiet operation | Higher initial cost, needs hose and regulator |

Challenges of Red/Black Gas

- High pressure increases wear on nozzles, valves, and seals.

- Prolonged use without upgrades can lead to cracking of internal parts like the hammer and other trigger components.

- Recommended only for GBB guns with high-quality steel or aluminum trigger mechanisms, such as the VFC Umarex HK416.

Gun type vs. gas

- GBB pistols: Green Gas, Red Gas in cold, CO₂ (depending on design), beware of slide type.

- GBB rifles: Usually CO₂ or stronger Orange / Red Gas – more durable construction, often requires upgraded parts.

- GNB Sniper Rifles (Bolt-Action): More stable gases like CO₂, HPA, or Black Gas – consistency, ambient temperature, and quality of internals matter.

Stability and seasons

- Most stable: HPA – performance not affected by temperature.

- Most temperature-sensitive: Green Gas, especially in winter loses pressure.

- CO₂: Better stability in winter but may be over-pressurized in heat – always handle with care.

Temperature affects gas pressure, meaning power drops in winter and rises in summer. We recommend choosing the gas according to current conditions and your gun’s construction.

Powered by Froala Editor