CNC Machining

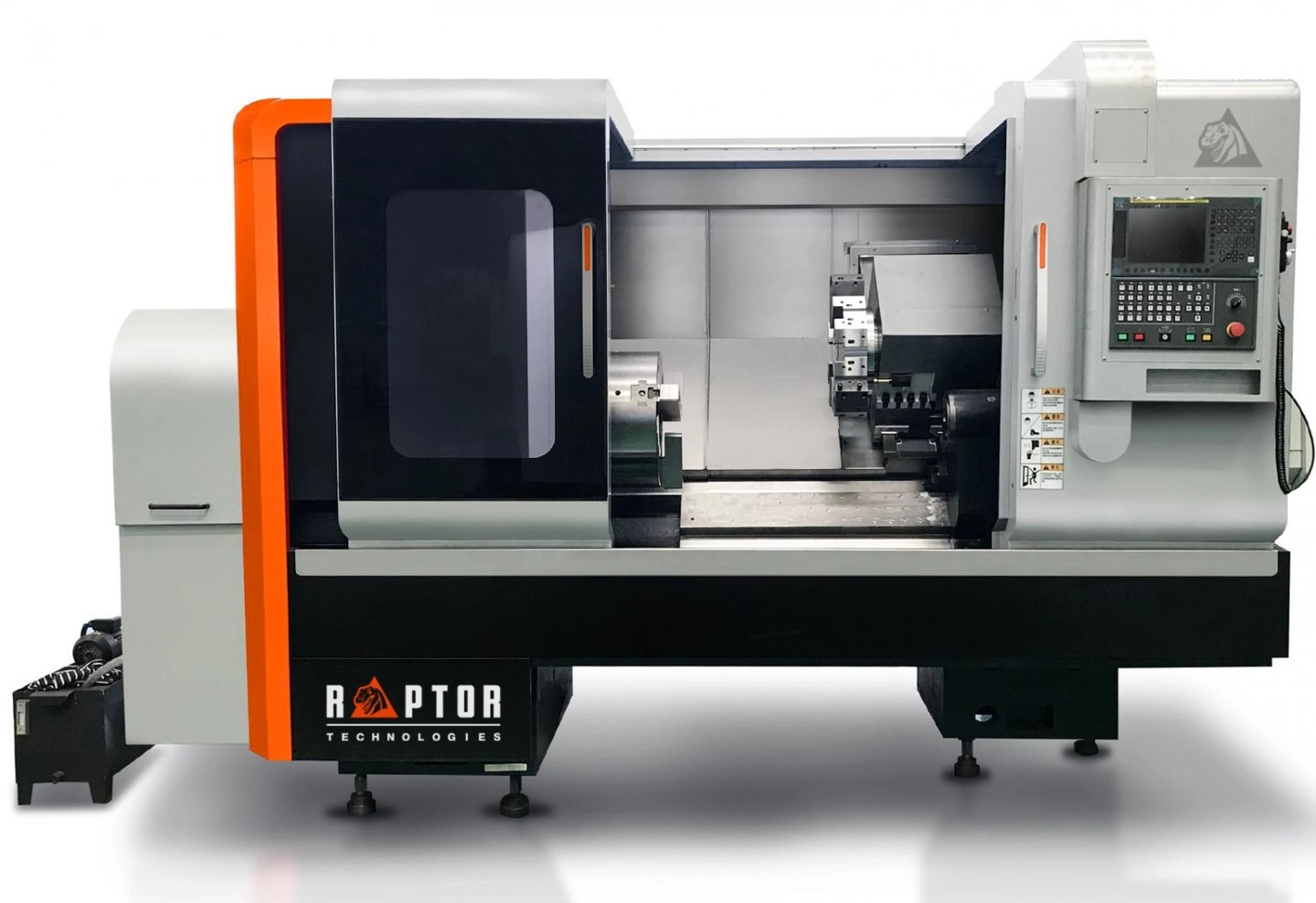

CNC Machining (Computer Numerical Control) is a manufacturing process where cutting tools are computer-controlled to create highly precise components from metal, plastic, or other materials. CNC machines operate based on pre-programmed instructions, ensuring repeatable precision, high quality, and production efficiency. In airsoft, CNC machining is primarily used for manufacturing durable gearboxes, precise internal parts, and hop-up chambers as well as for producing robust and perfectly fitted gun bodies. Below is an example of the RAPTOR CNC lathe.

How does CNC machining work?

- Programming: CNC machines operate using G-code, which defines tool movements, cutting speed, and other parameters.

- Automation: Once the program is loaded, the CNC machine operates autonomously, minimizing human errors.

- Multi-axis machining: Modern CNC machines feature multiple axes (e.g., 3-axis, 5-axis), allowing the creation of complex and precise components.

Advantages of CNC machining:

- High precision: CNC machines can produce parts with minimal deviations.

- Repeatability: Every produced piece is identical, which is crucial for mass production.

- Efficiency: Automated processes reduce production time and increase productivity.

- Complex shapes capability: CNC technology enables the creation of detailed and intricate components that would be difficult to manufacture manually.

Disadvantages of CNC machining:

- Higher initial costs: CNC machines and their maintenance are expensive.

- Requires skilled operators: Programming and setting up CNC machines require experience.

- Time-consuming programming: Preparing a CNC program can be complex, especially for intricate components.

Powered by Froala Editor