HRC

HRC (Rockwell Hardness C) is a designation of material hardness according to the Rockwell C scale. It indicates how resistant a material is to penetration by a foreign body (indentation) and is used primarily for hardened steels and heat-treated metal parts. HRC is therefore the standard hardness designation for hardened steels on the Rockwell C scale. It expresses resistance to indentation and wear and is a key parameter for evaluating the quality of firearm and airsoft components. A correctly chosen HRC value means longer service life, reliability, and safe operation of the part in a weapon.

How is HRC hardness measured?

In Rockwell HRC testing, a diamond cone (the so-called Brale indenter) is pressed into the material under a precisely defined load. The instrument then measures the depth of the indentation and converts it into a numerical HRC value.

A simple rule applies: the higher the HRC value, the harder the material.

What does HRC represent in practice?

- Wear resistance – higher HRC means less wear due to friction.

- Surface strength – the material deforms less.

- Brittleness – extremely high hardness can mean lower toughness.

Typical HRC values

- 20–30 HRC – softer steels, structural parts.

- 35–45 HRC – commonly hardened mechanical components.

- 45–55 HRC – quality firearm parts, gears, bolts.

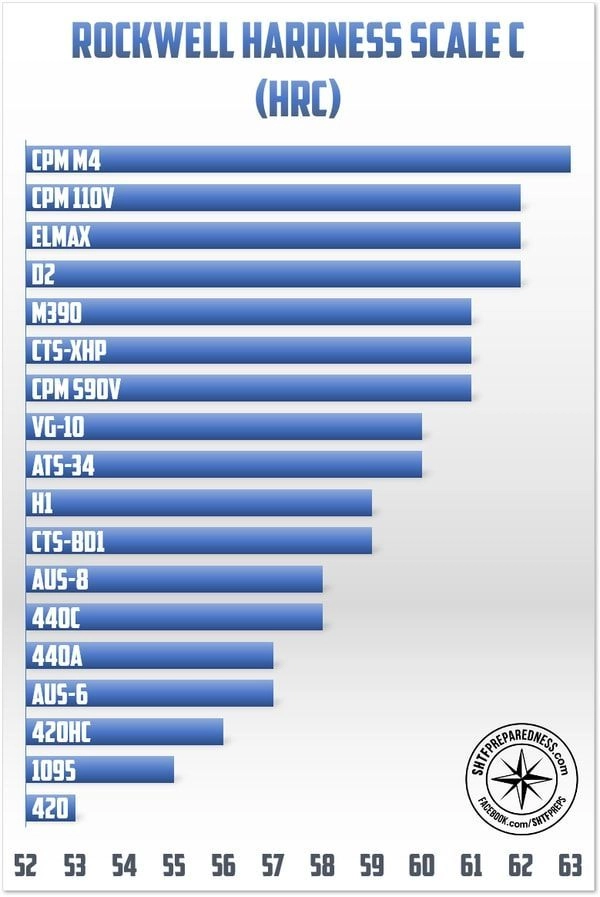

- 55–65 HRC – tools, knives, extremely stressed components.

HRC and firearms / airsoft

In firearms and airsoft components, HRC is used to assess quality, for example, in:

- gears,

- hammers and sears,

- shafts and pins,

- bolts and carriers.

Too low hardness means rapid wear, while excessively high hardness can lead to cracking. Quality manufacturers therefore choose a balanced compromise between hardness and toughness.

HRC vs. other hardness scales

- HRC – hardened steels (most common for firearms).

- HRB – softer metals (brass, mild steel).

- HV (Vickers) – very precise method for thin layers.

- HB (Brinell) – cast irons and coarser materials.

Powered by Froala Editor